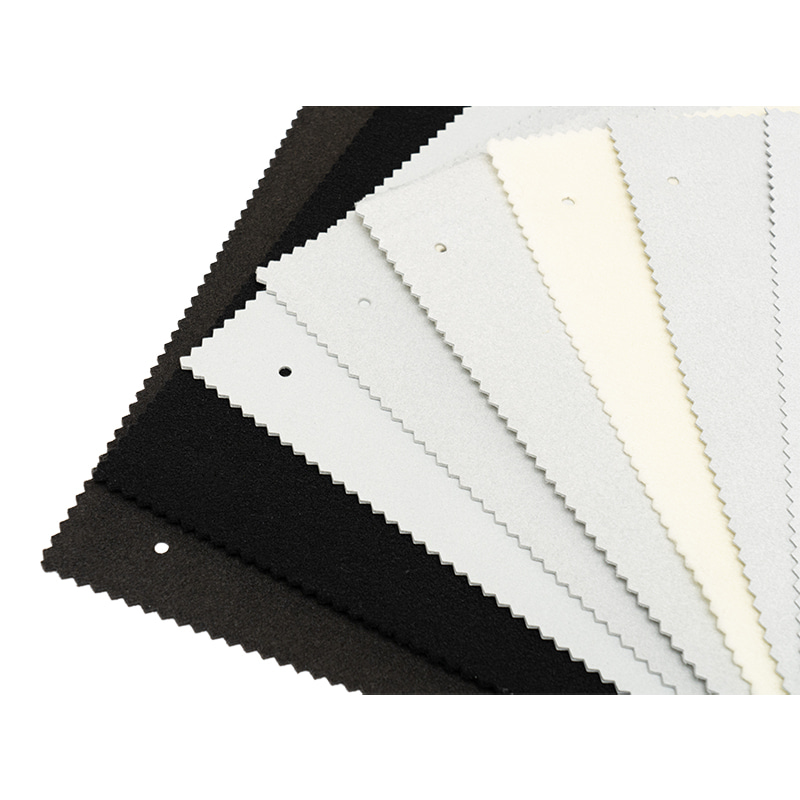

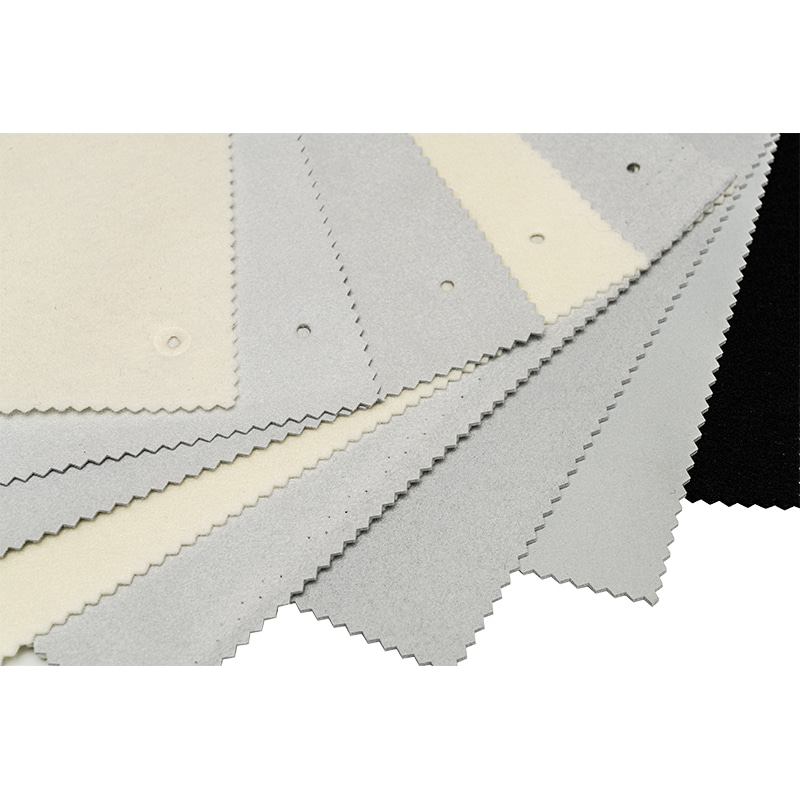

The Sustainable Production Process Behind Water-Soluble Polyester Sea-Island Fiber Nonwoven Fabric

The creation of

water-soluble polyester sea-island fiber nonwoven fabric begins with the careful synthesis and extrusion of the two primary components: the polyester "sea" and the polyvinyl alcohol (PVA) "island." This fiber structure is unique because it integrates two distinct materials, one of which will be soluble in water. The polyester, which forms the core of the fiber, is produced through a polymerization process where the raw materials are melted and combined under heat. This polymer is then extruded through spinnerets—tiny nozzles that help shape the fiber. Simultaneously, the polyvinyl alcohol, known for its water-soluble properties, is processed into fine filaments that create the island component within the polyester sea. These two components are interwoven, with the PVA forming islands throughout the polyester fiber. The importance of this dual-component structure lies in its ability to combine the benefits of polyester, a durable and versatile material, with the unique, eco-friendly characteristics of polyvinyl alcohol. The polyester core provides the fiber with strength and durability, while the PVA islands contribute to the fiber’s solubility in water. Ningbo Hengqide Chemical Fiber Technology Co., Ltd. has refined this process to ensure that the fiber's physical properties remain intact throughout production.

The key to sustainability in the production of water-soluble polyester sea-island fiber nonwoven fabric lies in the water-based reduction process. Unlike traditional island fiber production, which requires the use of toxic chemicals such as toluene or dimethylformamide (DMF) to dissolve the polyvinyl alcohol component, this innovative technique uses only water to reduce the fiber. In the reduction process, water at a temperature of 95°C is applied to dissolve the PVA component from the polyester core. This technique eliminates the need for harmful solvents that are commonly associated with pollution and health hazards. The benefits of using water-based reduction are far-reaching. By avoiding toxic chemicals, the entire production process becomes more eco-friendly, reducing the carbon footprint and the potential for contamination of surrounding environments. Using water as a solvent is much more energy-efficient and sustainable compared to traditional chemical-based methods, which often require the use of excessive amounts of energy and chemicals. The PVA component is removed through a natural process, ensuring that no harmful byproducts are left behind. The result is a fabric that maintains its strength and quality while adhering to strict environmental standards.

In the next stage of the production process, the fibers are immersed in a water-based resin that helps bind the fibers together. The resin is an essential component in the coagulation process, where the fibers are treated in such a way that they remain intact and cohesive. The use of water-based resin is an integral part of the fabric's overall sustainability. Traditionally, resin coagulation may involve the use of harsh chemicals or solvents, but Ningbo Hengqide Chemical Fiber Technology Co., Ltd. employs a water-based approach to avoid introducing toxic substances into the environment. This not only enhances the sustainability of the production process but also ensures that the final fabric does not contain any harmful chemical residues. The water-based resin helps to maintain the structural integrity of the fibers and enhances the fabric's durability. Without the use of chemical solvents, the fabric retains its strength, flexibility, and other key properties, ensuring that the final product is both functional and safe for consumers. This eco-friendly resin process makes the fibers easier to recycle and repurpose, contributing to a circular economy. As the textile industry increasingly moves toward sustainability, the use of water-based resin in coagulation represents a critical step toward achieving a more environmentally responsible production cycle.

After the fibers are treated with the water-based resin, they undergo hot water coagulation at a temperature of 95°C. This step plays a crucial role in the removal of the polyvinyl alcohol (PVA) component from the fibers. The hot water helps dissolve the PVA islands from the polyester sea, leaving behind a clean, durable microfiber fabric. This step is critical in ensuring that the fabric remains strong and flexible, while also ensuring that the PVA material is completely removed. Hot water coagulation is an energy-efficient and environmentally friendly process. Unlike traditional methods, which may involve the use of heat-sensitive chemicals, the water-based technique requires only hot water to complete the fiber reduction. This method significantly reduces the environmental impact of the production process by minimizing energy consumption and eliminating the need for chemical additives. Hot water coagulation ensures that the fiber's physical properties, such as its tensile strength and flexibility, are not compromised during the reduction process. The result is a high-quality fabric that is strong, durable, and environmentally responsible. By relying on hot water rather than chemicals, Ningbo Hengqide Chemical Fiber Technology Co., Ltd.’s production process demonstrates a commitment to sustainability while delivering superior quality fabrics.

The significant environmental advantage of the production process for water-soluble polyester sea-island fiber nonwoven fabric is the complete elimination of harmful chemicals. Traditional island fiber production methods often rely on toxic solvents, such as toluene and DMF, which can have detrimental effects on both human health and the environment. These chemicals are not only harmful to workers involved in the manufacturing process but also pose risks to ecosystems when they are released into the environment. By using water-based reduction, Ningbo Hengqide Chemical Fiber Technology Co., Ltd. has revolutionized the process by completely removing the need for these toxic chemicals. The use of only water as a solvent means that no harmful byproducts are produced during the fiber's creation. This is particularly beneficial for the environment, as it eliminates the potential for contamination of air, water, and soil with hazardous substances. The absence of harmful chemicals in the production process ensures that the final product is safe for consumers, making it ideal for use in products such as clothing, upholstery, and medical textiles. The reduction in chemical usage also improves the safety and working conditions for factory workers. By eliminating exposure to toxic chemicals, the workplace becomes safer, with fewer health risks associated with the production process. This is a significant benefit, as it aligns with global efforts to improve worker safety and minimize industrial hazards.

Energy efficiency and resource conservation are two key considerations in the production of water-soluble polyester sea-island fiber nonwoven fabric. The process developed by Ningbo Hengqide Chemical Fiber Technology Co., Ltd. has been designed to minimize energy consumption and reduce the overall environmental footprint of the production cycle. Traditional textile manufacturing methods often require significant amounts of energy to operate machinery, heat chemicals, and maintain high processing temperatures. However, the water-based reduction and coagulation techniques used by the company are much more energy-efficient. The hot water coagulation process, for example, uses water at 95°C to dissolve the PVA component without the need for additional heating elements or excessive energy consumption. This reduces the overall energy requirements of the process, leading to lower carbon emissions and a more sustainable production cycle. Water-based reduction eliminates the need for energy-intensive chemical treatments, further reducing the environmental impact. The company’s commitment to resource conservation extends beyond energy efficiency. Water is a critical resource in the production process, and Ningbo Hengqide Chemical Fiber Technology Co., Ltd. has implemented measures to recycle and reuse water throughout the manufacturing cycle. By treating and reusing water, the company minimizes the strain on local water supplies and reduces waste. This resource-efficient approach not only lowers production costs but also aligns with global efforts to conserve water and reduce industrial waste.

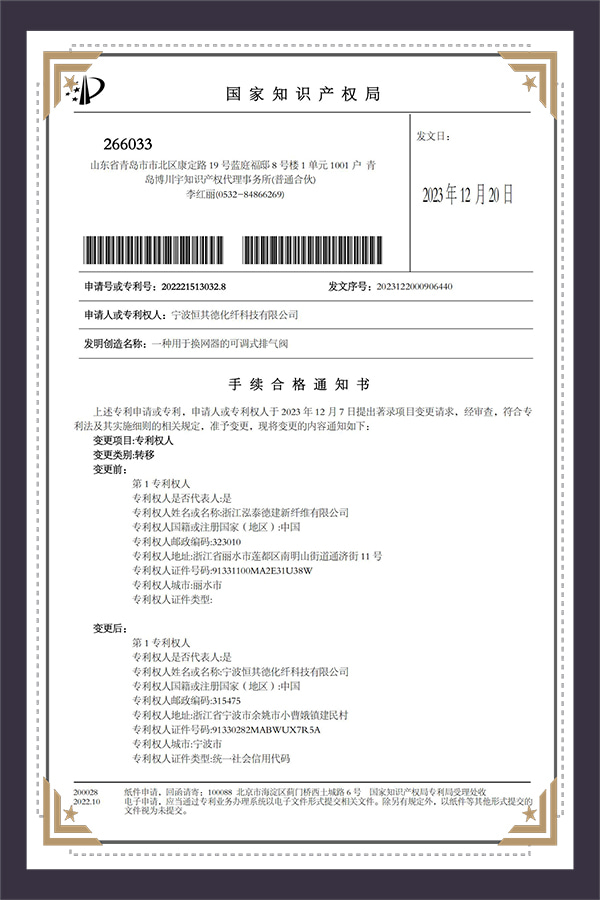

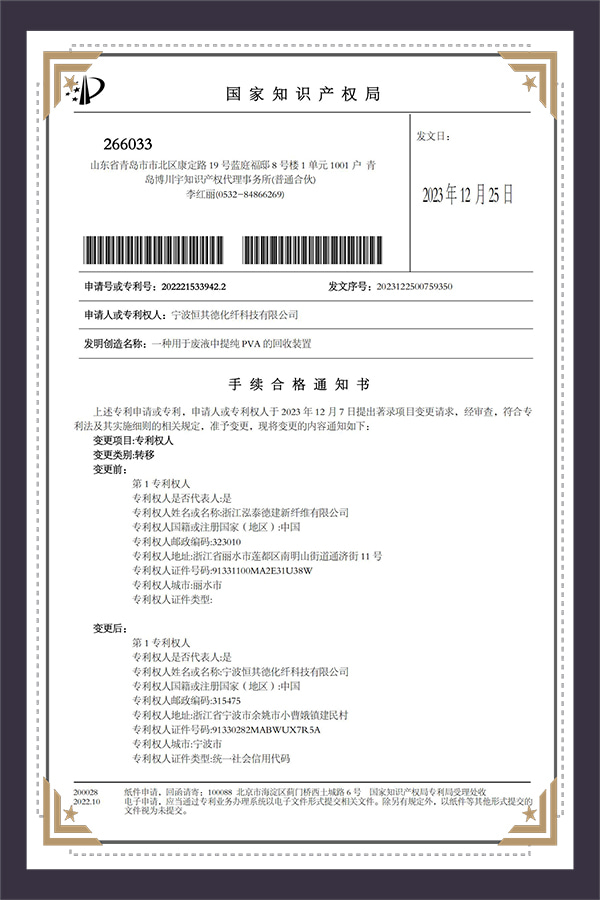

To ensure that its production process aligns with international environmental standards, Ningbo Hengqide Chemical Fiber Technology Co., Ltd. conducts thorough environmental impact assessments (EIAs) for each stage of production. These assessments evaluate the environmental footprint of the entire process, from the sourcing of raw materials to the final disposal of products. By assessing the environmental impact at each stage, the company can identify areas for improvement and implement sustainable practices that reduce waste, energy consumption, and pollution. The company has also obtained various certifications that validate its commitment to environmental sustainability. These certifications include ISO standards for environmental management, water and energy usage, and waste reduction. The company’s adherence to these standards ensures that the water-soluble polyester sea-island fiber nonwoven fabric meets the highest levels of environmental responsibility. By prioritizing sustainability and conducting regular environmental impact assessments, Ningbo Hengqide Chemical Fiber Technology Co., Ltd. not only ensures the integrity of its production process but also helps set a benchmark for other manufacturers in the textile industry. This commitment to sustainability reinforces the company’s role as a leader in green manufacturing and positions it as a key player in the global effort to reduce the environmental impact of textile production.

英语

英语 中文简体

中文简体