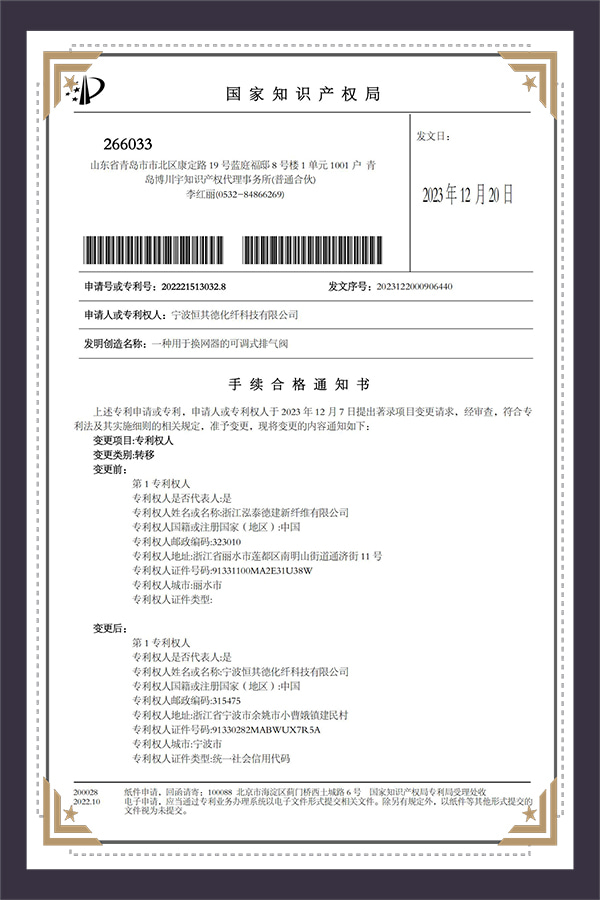

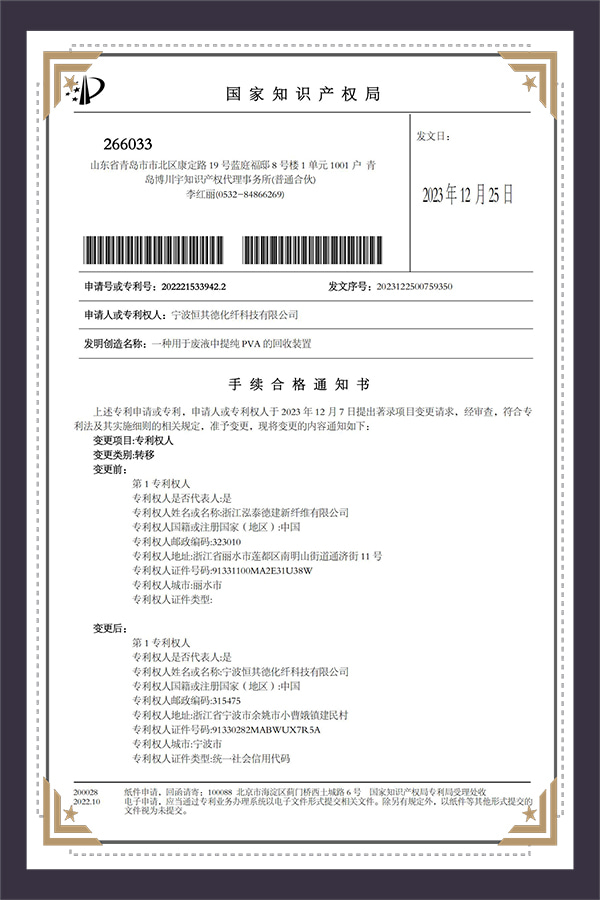

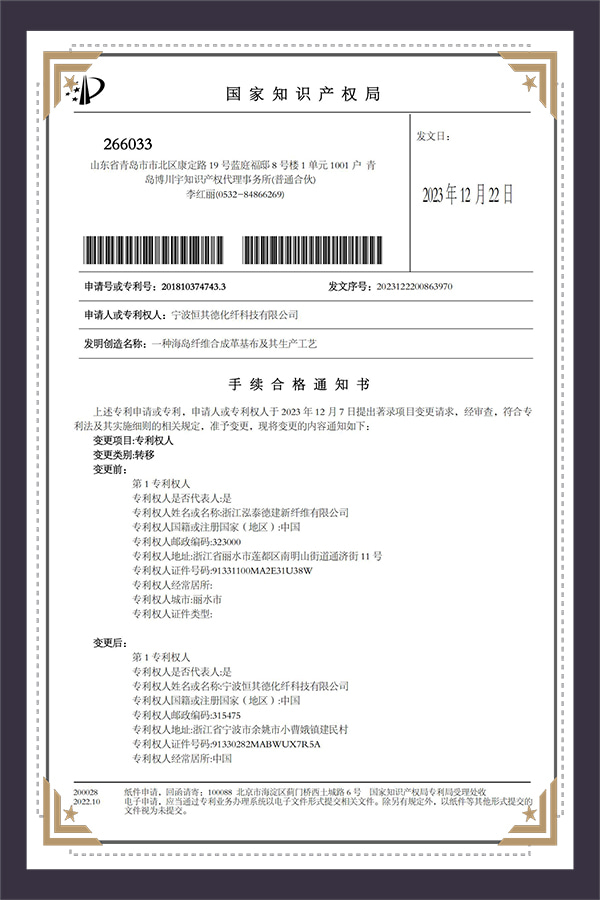

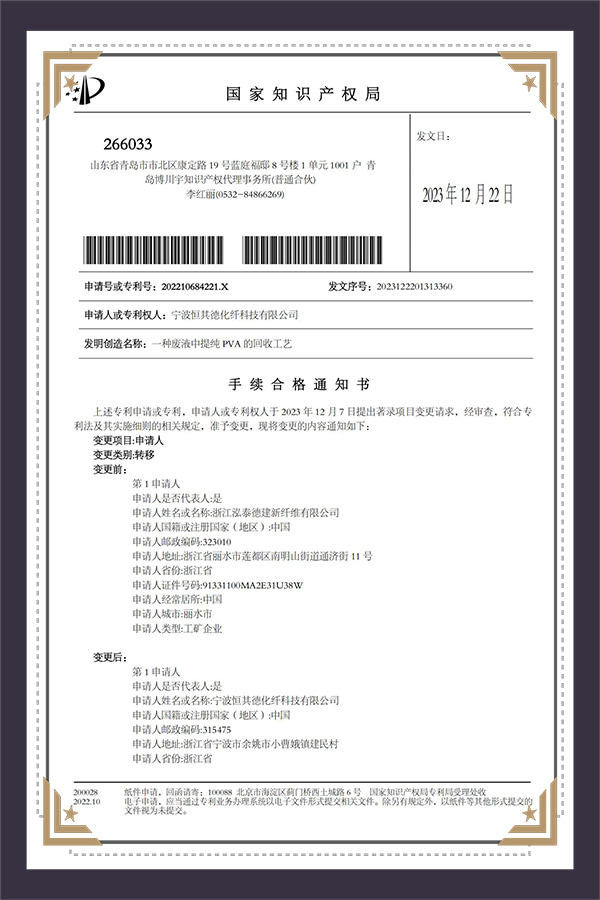

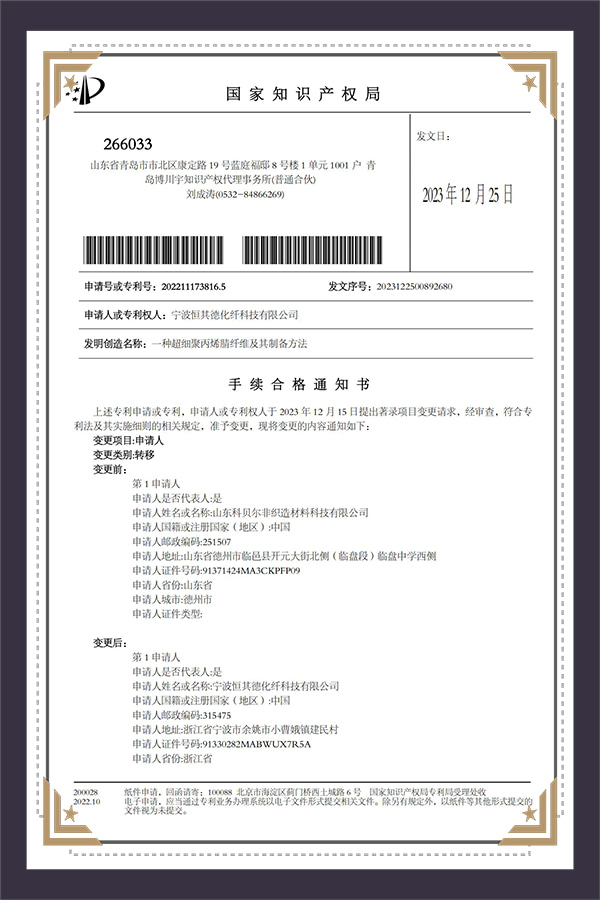

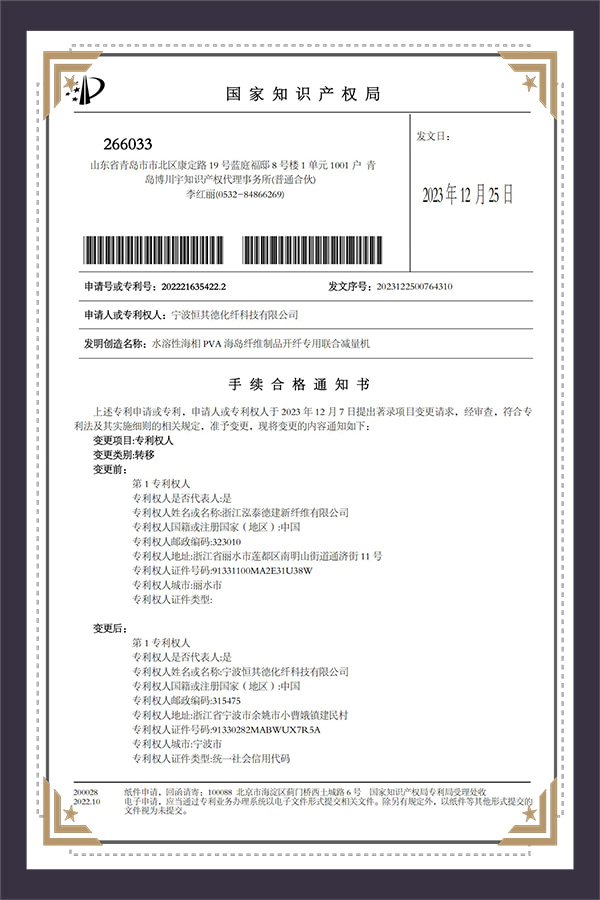

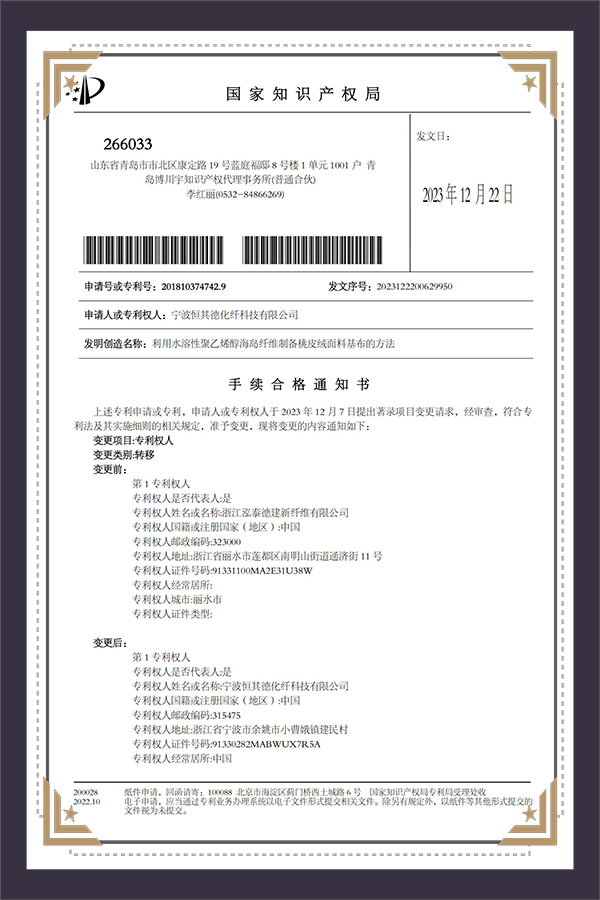

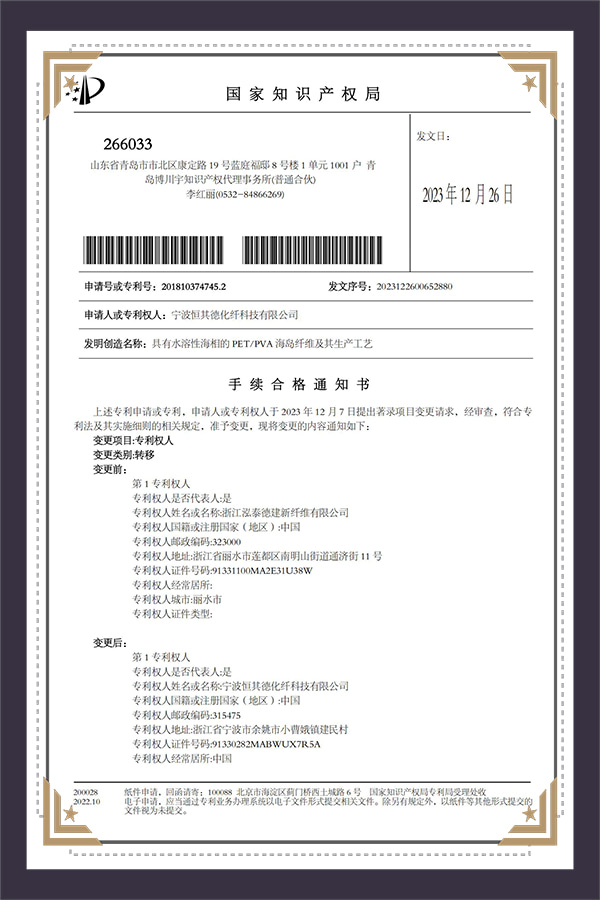

In conventional manufacturing processes, the production of synthetic fibers, leather alternatives, and other materials often involves significant chemical waste, high energy consumption, and emissions of greenhouse gases. These issues contribute to pollution, ecosystem degradation, and increased carbon footprints. Water-based microfiber base, on the other hand, is produced using a process that significantly reduces or even eliminates many of these harmful side effects. By replacing solvents like benzene or other harsh chemicals with water, manufacturers can produce a material that is not only high-performance but also much safer for the environment. For instance, traditional microfiber production can involve the use of toxic chemicals, such as formaldehyde, and require extensive waste management protocols to mitigate the environmental impact. Water-based microfiber base, however, utilizes water as a solvent and adopts more energy-efficient production methods. This approach significantly reduces the emissions of volatile organic compounds (VOCs) and lowers the overall environmental impact, particularly in terms of water and air pollution. Ningbo Hengqide Chemical Fiber Technology Co., Ltd., an industry leader in water-soluble island fibers, has played a critical role in advancing this technology. The company's ongoing research and innovation have led to a production process for water-based microfiber base that not only reduces waste gas emissions but also minimizes the use of harsh chemicals. This commitment to sustainability has positioned Ningbo Hengqide as a pioneer in the field, setting an example for the broader industry to follow.

The process of creating water-based microfiber base involves innovative techniques that differ significantly from traditional methods. Instead of relying on chemical-based solvents, this production method leverages water to dissolve the fibers, which is not only safer but also more efficient. Water-soluble island fibers, which serve as the building blocks for water-based microfibers, are created by dissolving the core material in water and subsequently solidifying it into microfibers. This process produces fibers that are finer than those created using traditional methods, resulting in a superior material that maintains both structural integrity and performance. The use of water in production has far-reaching environmental benefits. One of the primary concerns in manufacturing is water use—especially in industries like textiles, which consume vast amounts of water for dyeing, cleaning, and finishing processes. The innovative technologies employed by Ningbo Hengqide Chemical Fiber Technology Co., Ltd. have helped address this concern by making water a central component of the production process, rather than a waste byproduct. By using water-soluble sea-island fibers and minimizing water waste, the company has developed a highly efficient manufacturing process that reduces water consumption without compromising quality. Water-based microfiber production also uses fewer harmful chemicals than conventional methods, which often involve toxic dyes, bleaches, and finishing agents. This contributes to the reduction of hazardous waste generated during production, making water-based microfiber base a truly eco-friendly alternative to traditional materials.

Energy consumption is another critical factor in manufacturing sustainability. Conventional microfiber production processes often require significant amounts of energy, especially during the drying and finishing stages. The use of high temperatures and energy-intensive equipment leads to higher carbon emissions, contributing to global warming and resource depletion. However, water-based microfiber base production offers a more energy-efficient solution, thanks to its reliance on water and lower temperatures during processing. Ningbo Hengqide Chemical Fiber Technology Co., Ltd. has optimized the production process of water-based microfiber base to further reduce energy consumption. The company’s focus on low-temperature, water-based processes has resulted in significant energy savings, further enhancing the environmental benefits of the material. By utilizing less energy-intensive methods, the company contributes to a lower carbon footprint, in line with global efforts to reduce greenhouse gas emissions and mitigate climate change. In addition to energy efficiency, the company's approach to producing water-based microfiber also focuses on resource conservation. By using renewable resources like water and natural fibers, Ningbo Hengqide’s production methods reduce dependency on non-renewable resources such as petroleum-based materials. This shift not only promotes sustainability but also positions water-based microfiber base as a forward-thinking alternative in the industry.

Waste reduction is an integral part of any eco-friendly manufacturing process. Traditional methods of producing textiles and leather substitutes often involve significant waste, both in terms of material scraps and byproducts. In contrast, water-based microfiber production is designed to minimize waste generation. The water-soluble sea-island fibers used in the production process allow for a high level of material recovery, with little to no waste left over from production. Ningbo Hengqide Chemical Fiber Technology Co., Ltd. has pioneered in developing closed-loop production systems that maximize material recovery and minimize waste. The company’s innovative water-soluble sea-island fiber technology ensures that the majority of the materials used in microfiber production are either repurposed or recycled, further reducing the environmental impact. Additionally, the water-based nature of the fibers makes them biodegradable, meaning that end-of-life disposal will have less of an impact on the environment compared to synthetic alternatives. As the textile industry faces increasing pressure to adopt more sustainable practices, water-based microfiber base offers a clear solution for reducing waste, lowering emissions, and promoting circularity. This approach aligns with global sustainability goals, particularly those related to the circular economy and zero-waste initiatives.

As the world becomes more environmentally conscious, manufacturers are being held to higher standards when it comes to sustainability. This is especially true in industries like textiles, where there are growing concerns about pollution, waste, and chemical use. Water-based microfiber base is at the forefront of meeting these standards, offering a material that can be both high-performance and eco-friendly. One of the key drivers of global sustainability in manufacturing is the adoption of international standards such as ISO 14001 for environmental management systems, and the Global Organic Textile Standard (GOTS) for organic textiles. Water-based microfiber base aligns with these standards by reducing chemical waste, minimizing water usage, and promoting energy-efficient production processes. Companies like Ningbo Hengqide Chemical Fiber Technology Co., Ltd. have embraced these standards in their manufacturing practices, ensuring that their products meet the highest environmental criteria. Their commitment to sustainability not only enhances their product offerings but also sets a standard for other manufacturers to follow. The increasing adoption of certifications like OEKO-TEX and GOTS further supports the demand for sustainable materials. Water-based microfiber base is well-positioned to meet these certifications due to its natural, biodegradable components and low environmental impact. By choosing this material, manufacturers can align their operations with global sustainability trends and meet the growing expectations of consumers for eco-friendly products.